Supply Chain Redesign (33 Inpatient Units)

Challenge: To standardize 33 clean supply room, reduce “stock outs” and meet demand of supplies, adjust supply levels and wasted inventory to reduce costs, and to minimize supplies stored outside designated bins. “Reduce Variability, Build Predictability”

Results/Outcomes:

Standardized Supply Rooms with 8 categories (staff have the ability to navigate any supply room with reduced time wasted on finding supplies)

Reduction in stock outs due to accurate supply levels (1,353 to 909)

Core Team: Materials Management (Supply Chain) Nursing, Senior Project Manager, Various Department Leadership

Timeline: 12 weeks

Week 1: Define

Project Kick-off/Alignment

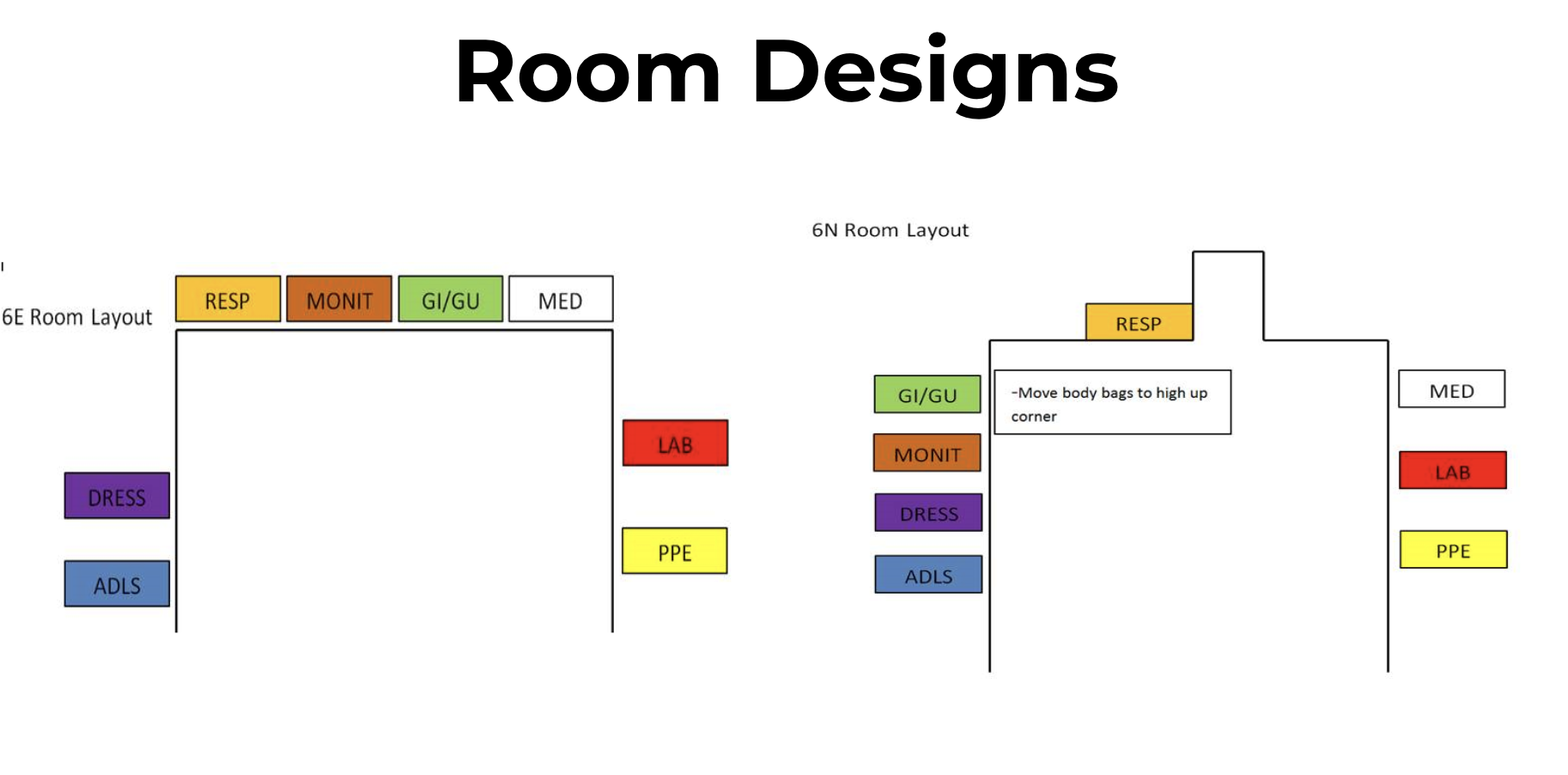

Inpatient Units Layout Overview

Project Charter

Project Plan

Week 2: Measure

Current State Assessment

Stakeholder Interviews (Nurses, Supply Chain Team, etc.)

Current State Process Maps

KPIs and Data Requests

Week 3: Analyze

Data Analysis

Accurate/Complete Data

Clarify Inconsistencies

Data Findings

Week 4: Design and Improve

Current state (process maps, performance metrics, stakeholder Interviews)

Supply chain levels analysis (by supply category, supply type, bin sizes, min/max levels, supply quantity/ordering information, cost, lead/lag time, etc.)

Action plan

Weeks 5-12: Implementation

Redesign

Update “Par Levels” min/max

Match Bin Size (physical changes)

Adjust weight detection of bins based on size and supply for automatic re-ordering

Prep Rooms

Relabel

Count/locate

Review bin sizes

Add/remove items

Room layout

Continuous Improvement

Adjustments to bin

Review and monitor adjustments

Skills Used

Lean Six Sigma, Project Management, Excel, Powerpoint, Word, Sharepoint, Supply Chain Management